The automatic packaging line of new energy cells is qualified for packaging and delivery.

Machine Name:

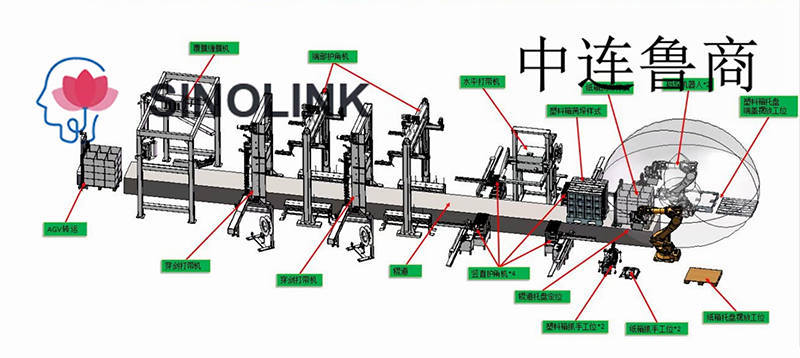

Automatic new energy battery transportation, palletizing, wrapping and laminating with corner protection, strapping and corner protection, AGV unmanned trolley loading and unloading, debugging qualified, and delivering to client’s site.

Equipments Picture:

The following is the basic information of the project:

Basic requirements of the project

1. Details of battery packaging materials

S.N | 182 Cell Packing Specification | 210 Cell Packing Specification | 230 Cell Packing Specification |

1 | 1250*1060*130mm | 1250*1180*130mm | 1250*1260*130mm |

2 | 505*396*273mm | 565*396*273mm | 605*396*273mm |

Wrapping adding long corner protection

Long corner protection specifications: 960mm length×5mm×50mm (the specific size is subject to the actual size of the customer, and the length is 850~1250mm adjustable)

Strapping machine with short corner protection:

Short corner protection specifications: 120mm×5mm×50mm

Packing height:≤1500mm

Limited space on site:

1) Length control in: 10000mm

2) Width control in: 5000-6000mm

3) The sword strapping machine uses a double sword piercing type.

2. Efficiency: The state of the incoming pallet is an average of 12 minutes per pallet

3. Packaging mode:

1). Docking with demand-side AGV, AGV positioning accuracy ± 10mm;

2). Each specification will be fixed production, periodically switched;

3) Strap type tic-tac-toe strapping;

4). 4 corner protection needs to be placed on strapping corner, tentatively 4 short corner protection (common specifications of photovoltaic panels: 100mm long);

5). Put 4 long protective corners in the vertical direction, the specifications of the long protective corners are fixed, and the wrapping needs covering film.

Related Products

Submitted successfully

We will contact you as soon as possible