Fully Automatic Trayless Online Wrapping Packaging Machine

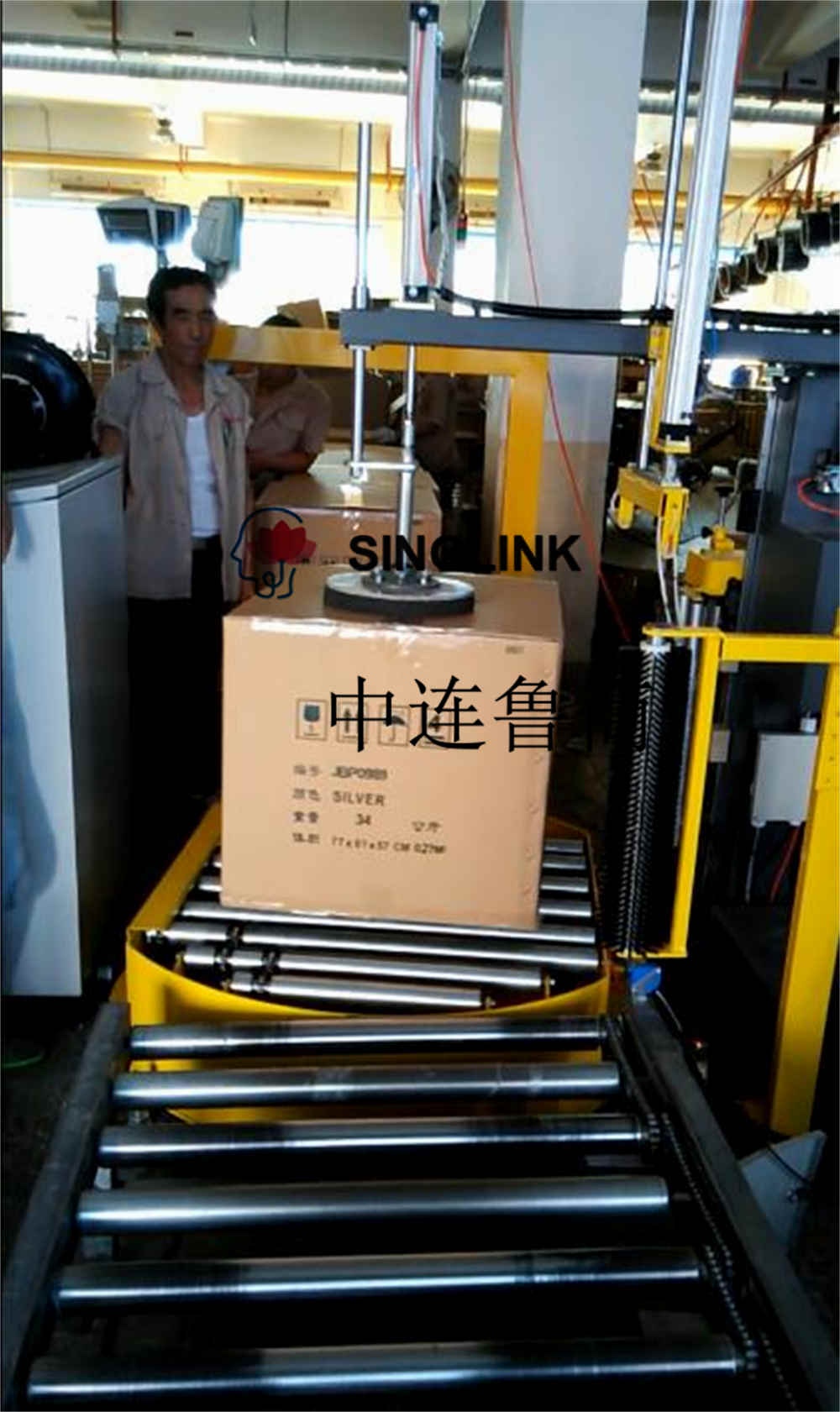

Fully Automatic Trayless Online Wrapping Packaging Machine

Proposal

Contents:

1. Packaging overview

2. Technical data

3. Working conditions

4. After-sales technical services

5. Main components

6. Communication between the winding machine and the main control machine

1. Packaging overview

1.1 This equipment is a special equipment for automatically winding stretch film onto the carton. It plays the role of dustproof, moisture-proof and anti-bulk packaging of goods, thereby playing a special equipment for product protection, saving packaging costs, reducing workers' labor intensity and improving packaging effects.

1.2 The carton is automatically transported into the winding machine, the top is automatically pressed down, the film is automatically on, the winding machine is automatically started according to the set packaging parameters to realize the packaging process, the winding is completed, the film is automatically broken, the top is automatically rising, and the carton is automatically transported out of the winding packaging station.

1.3 The next cargo recycling packaging begins.

2. Technical data

Main performance:

Membrane frame system: open door membrane frame

Lifting system: optional frequency conversion speed regulation

Control system: PLC control, can set the number of top and bottom circles of the package, the number of wrapping layers

Pressing device: pneumatic pressure arm, safe and stable

Main parameters:

Wrapping specification L: 550-800mm W: 450mm-480mm H: 350-630mm

Packing efficiency: 60-100 pieces/h (depending on customer's specific packaging requirements)

Turntable speed: 0-20rpm speed frequency conversion adjustable

Automatic film breaking: automatic film clamping, automatic film breaking

Conveying speed: 6-8m/s

Conveyor table height: 750mm

Turntable load: 200kg

Total weight: 380kg

Dimensions: 1700mm×820mm×1760mm (subject to specific drawings)

Motor power/voltage: turntable 0.37kw, diaphragm frame 0.37kw, column 0.37kw/AC220V, conveying: 0.37kw

3. Working conditions

Working system: three-shift production, 8 hours per shift, no less than 300 working days per year, 24 hours continuous operation.

Power parameters: 220V AC50HZ voltage fluctuation range +/-10%.

Operating conditions: ambient temperature 10-40°C relative humidity 10-90%.

4. After-sales technical services

1. All the whole machine implements one year free warranty responsibility from the date of installation and test acceptance. Provide lifelong technical and maintenance services.

2. After-sales service hotline provides technical support 24 hours a day. Common issues 15 minutes to troubleshoot. After-sales service specialists all over the country provide customers with timely and convenient on-site technical service support.

5. Main parts

PLC : Omron

Frequency converter: Omron

Touch screen : Kunlun tong

Photoelectric switch: Corey

Proximity switch: Omron

Low-voltage electrical appliance: Schneider

Magnetic valve: domestic well-known brand

Cylinder: domestic well-known brand

Limit switch : Schmersal

Main device : Schneider

Turntable gearmotor: domestic well-known brand

Conveyor gearmotor: domestic well-known brand

Membrane frame film gearmotor: domestic well-known brand

Membrane frame lifting gearmotor: domestic well-known brand

Bolts and other fasteners: 8.8 grade

DC24V-3A power supply needs to be provided separately, and the DC power supply is selected from Weidmüller

If you have special requirement, please talk with us at any time. We can customize it for you.

Ady

WhatsApp:+86 15634865861

Related Products

Submitted successfully

We will contact you as soon as possible