Fully Automatic Palletized Cargo Separation Pusher

Fully Automatic Palletized Cargo Separation Pusher

Project Name and Scope:

1. Project name: small package of edible oil without pallet whole stack on forklift project

2. Scope of supply:

Reduce outsourcing costs and save costs by adding a set of "pallet push and pull product lines". Meet the process requirements of pallet-free pallet stacking, meet production efficiency, and achieve safe production. Including but not limited to the following;

A, Two sets of conveyors (need to bring their own)

B, two push-pull devices

C, two hydraulic stations

D, forklifts block two

E, two sets of control system

The specific content is designed according to the site situation and the equipment supplier's own equipment characteristics.

3. Conditions provided by the factory:

The factory is responsible for connecting the power supply to the main control cabinet.

Voltage: 380V, 50Hz, 3 phases 5 wires, voltage fluctuation range± 10%.

Overall Technical Parameters:

1. Hydraulic pusher:

Pallet retention ejector, without side shift, without fork, without pallet retention function, the ejection structure is scissor structure

2. Load capacity 1500KG, load loss distance of about 280mm, horizontal center of gravity of about 135mm (subject to actual design)

3. Automatic control system: control mode: wireless control (5-10 meters), wireless operation button assembled on the right side of the forklift A-pillar, including Siemens PLC, frequency converter (inverter with control panel) or equivalent quality brand products, low-voltage electrical components choose Schneider or equivalent quality brand products, carbon steel electric control box, P+F photoelectric sensor or OMRON and other similar quality brand proximity switches, protection level is IP67; The terminal blocks are made of Weidmüller or equivalent quality brand products

4. Single oil circuit hydraulic station: mechanical connection, hydraulic oil flow 20-30L/min, pressure 150BAR;

5. Forklift protection device: 6mm thick carbon steel plate (subject to actual design)

6. All power cables, control cables, bridges and threading pipes required for all equipment connection adopt flame retardant cables, and the power cables are selected to obtain China's well-known brand products;

7. The electrical control cabinet adopts the lower inlet line, the lower outlet, and the ventilation and exhaust device is installed, and meets the IP65 protection level.

8. Motor power: 5.5KW (subject to actual design)

9. Push plate size: height 1700 * width 1350, push stroke: 1750

10. Push efficiency: 30 torr/hour

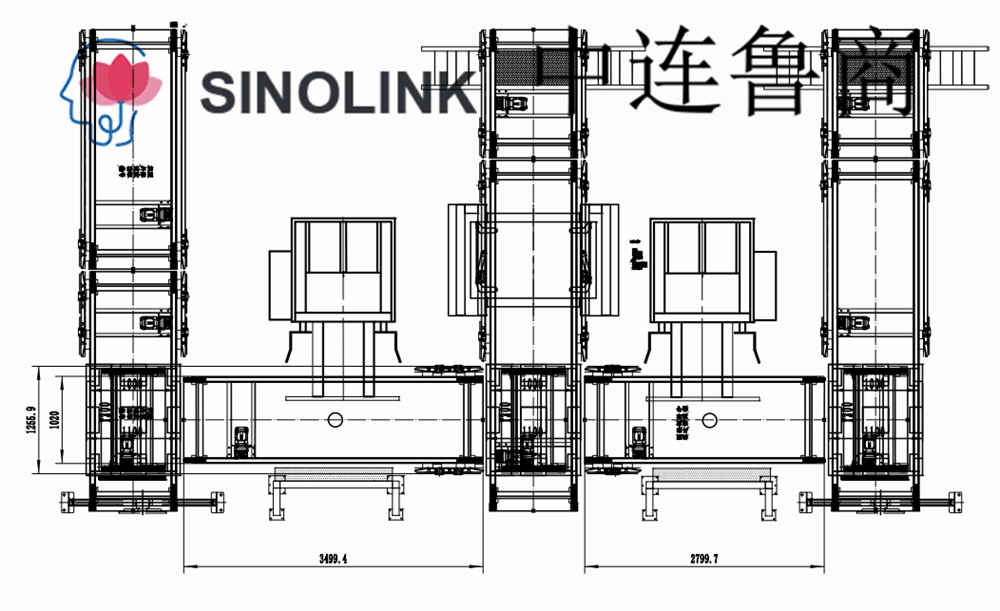

11. The conveyor under the pusher needs to be self-prepared:

1) Double row chain conveyor

2) Chain line speed: 16m/min

3) Length: 3500mm, 2800mm, width: 1320mm, conveyor elevation: 750mm

12. Equipment body color and protective color: according to cutomer's requirement.

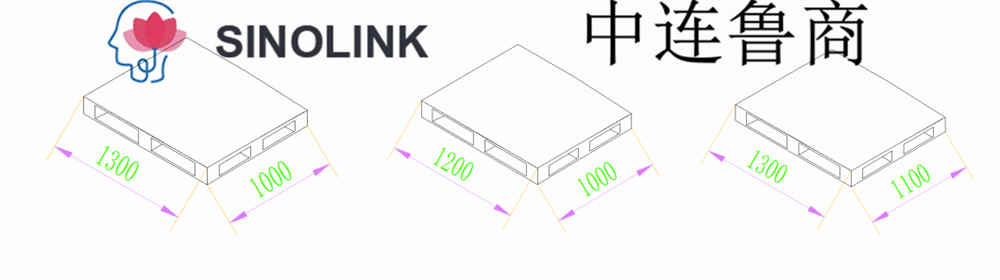

13. Pallet selection

Material: Plastic (Tian Zi Tuo)

Dimensions: L×W×H, mm: 1300× 1000×150, 1200×1000×150, 1300×1100×150

Fork direction: 1300/1200 direction (bottom fork pull, pusher push direction)

Structural form: double-sided pallet

Single weight, kg: 30

Load, kg: ≥ 1000

The conveyor must be designed with three solid pallet forms in mind, all of which can be used normally on the conveyor system .

Equipment arrangement

More information, please contact with us at any time!

Looking forward to your inquiry.

Ady

WhatsApp:+86 15634865861

Related Products

Submitted successfully

We will contact you as soon as possible