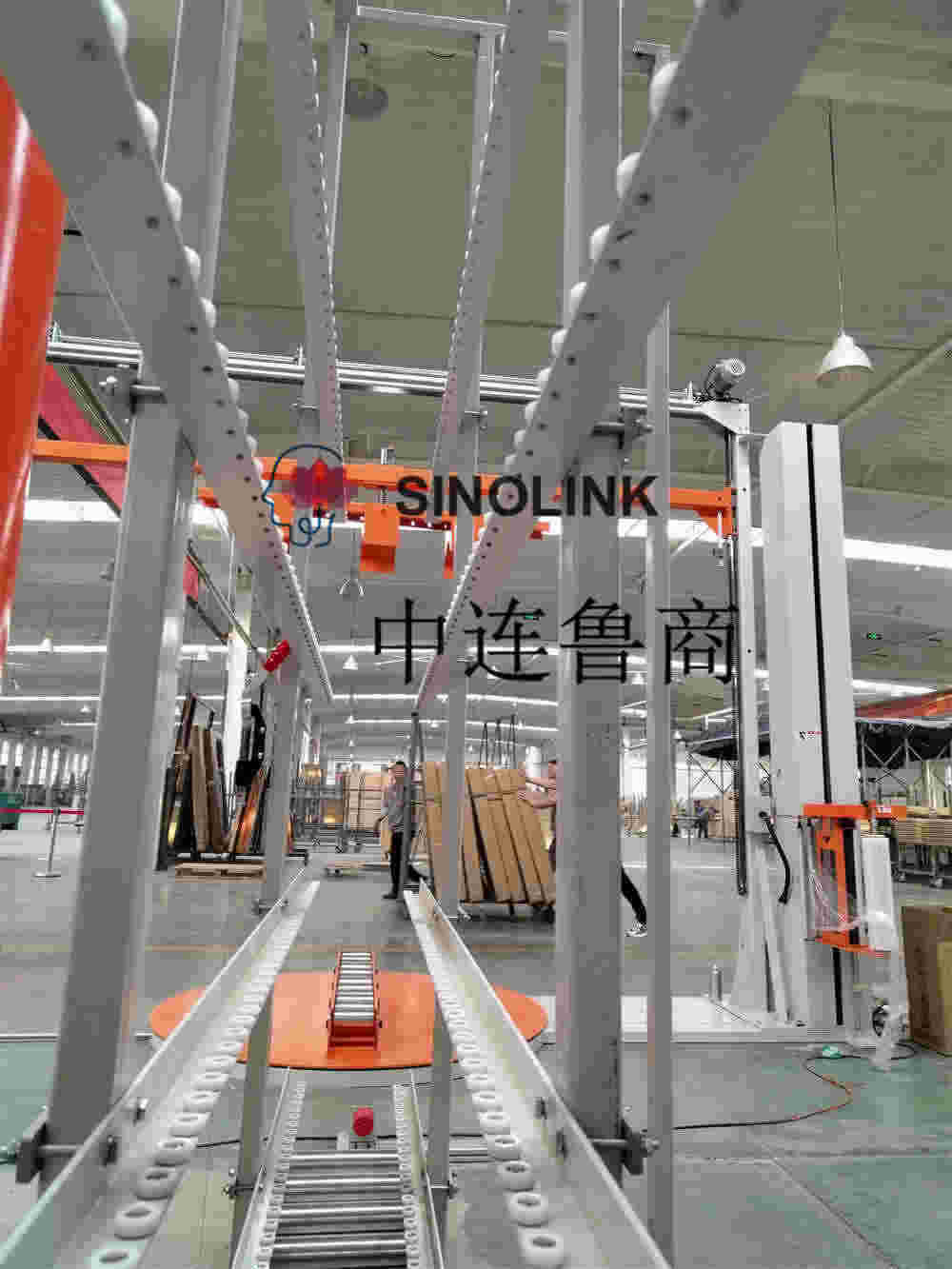

Non-standard Vertical Door And Window Wrapping Machine

The Non-standard Vertical Door And Window Wrapping Machine overview:

1. This equipment has the function of assisting in pushing doors and windows into the wrapping machine, and the name of the device is the connection and blessing of the non-powered conveyor line S-3500;

2. This equipment is a special equipment for automatically winding stretch film onto plate goods. It is a special equipment that plays the role of dust-proof, moisture-proof and anti-collision packaging for goods, saves packaging costs, reduces labor intensity of workers, and improves packaging effects;

3. After the door, window or door panel is pushed to the winding machine, the winding machine is started, the winding machine is automatically started, the packaging is completed, the winding machine is reset, and the next process begins.

Product performance advantages:

1. Touch screen control, easy to operate;

2. Pre-stretched film frame, 220V AC motor with inverter to adjust the tension force, change the speed regulation of the 24V DC motor and power box applied to the film frame in the same industry in China, and change the instability of tension force.

Technical Parameters:

1. Turntable diameter: 2000mm (this data is for reference, subject to the design of the technical department)

2. Wrapping specifications:

3. Packing specifications:

Utmost:3500mm (length)× 2600mm (height)× 150 (thickness) mm; Weight: about 500kg

Least:500mm (length), 500mm (height× × 80mm (thickness); Weight: about 50kg, turntable height: 78 mm

4. Turntable load-bearing: 2000kg

5. Weight: 1200kg

6. The power of the whole machine: about 2 kw

7. Power supply voltage: single-phase 220V

8. Turntable speed: 0~12 rpm

9. Packaging material: LLDPE stretch film

Thickness: 17~35μm

Width: 500mm

Membrane roll inside: 76.2mm

Maximum outer diameter of film roll: 240mm

Key features:

Control system:

1. The number of winding layers and the number of times can be set;

2. Photoelectric switch, automatically sensing the height of the goods

3. Reinforcement winding function, which can carry out special protection for a certain part;

4. Function of setting the time of crossing the top.

Turntable drive:

1. Turntable frequency conversion speed regulation is adjustable from 0~12 rpm;

2. The turntable drive is chain driven, and the positioning is accurate;

3. The turntable automatically resets;

4. The bottom of the turntable is equipped with forklift slots

Membrane Rack System:

1. Open the door film frame

2. The membrane frame is a dynamic pre-stretching mechanism, and the pre-stretching can reach 250%

3. Chain structure, stable and reliable;

4. The AC motor pulls the membrane, and the inverter adjusts the tension force;

5. The rising and lowering speed of the film frame and the speed of feeding the film can be adjusted respectively;

6. The number of top and bottom windings is controlled separately;

7. The follow-up mechanism of the membrane system can be pulled with one pull;

8. The power of the membrane frame lifting motor: 0.37kw

Touch Screen Features and Description:

1. Digital parameter setting: turntable speed, film frame lifting speed, film frame film output speed (0-50 can be set)

2. The number of winding circles at the bottom layer, the number of winding circles at the top layer, the number of times up and down, and the time of crossing the top can be set

3. Set up the manual strengthening function, which can strengthen and wrap the specific parts of the winding goods

4. Automatic diagnosis and detection of broken membrane and membrane deficiency and suspension processing function

5. Automatically sense the height of the goods

6. Freedom of origin and random start

Pressing function:

1 Electric top pressing

2. Power of top motor: 0.37KW (data for reference, subject to the design of the technical department)

3. Jacking stroke: 1500~2500mm

4. The pressing device should be equipped with a fixed fixture, and the number and structure of the fixture should consider the convenience and safety of large doors and windows

Incoming card slot:

1. Card slot size: 1200mm× 150mm×≥ 200mm (length× width, effective lifting height≥ 200mm turntable or more; The data here is for reference, and the design of the technical department shall prevail)

2. The surface of the conveying roller is galvanized and passivated

3. There are baffles on both sides of the card slot to effectively fix the wooden door

4. The height of the inner groove of the U-shaped groove is 30mm (the data here is for reference, subject to the design of the technical department)

Incoming connection and blessing non-powered conveyor line:

1. This equipment has the function of assisting in pushing doors and windows into the winding machine, and the name of the device is the connection and blessing of the non-powered conveyor line S-3500

2. Use with winding machine

3. The use process requires manual assistance to purchase

Equipment design convenience and other requirements

1. Add the start and pause device of the foot switch to facilitate the convenience of operation when manually packing

2. The color of the main body of the equipment: RAL9002 (gray and white), and the movable or rotatable part adopts RAL2004 (orange red) protective color

3. Other aspects of the equipment that involve optimization or improvement.

Main Component List of Non-standard Vertical Door And Window Wrapping Machine

S.N | Name | Brand | Remark |

1 | PLC | Dimensional control | |

2 | touch screen | Dimensional control | |

2 | Air switch | Tianzheng | |

3 | Turntable, membrane frame lifting inverter | Easy to drive | |

4 | Travel switch | Tianzheng | |

5 | Proximity switches | Omron | |

6 | Photoelectric switches | Panasonic | |

7 | buttons, indicators | Gangbo | |

8 | Geared motors | Liming or CUHK | (Domestic high quality) |

Related Products

Submitted successfully

We will contact you as soon as possible