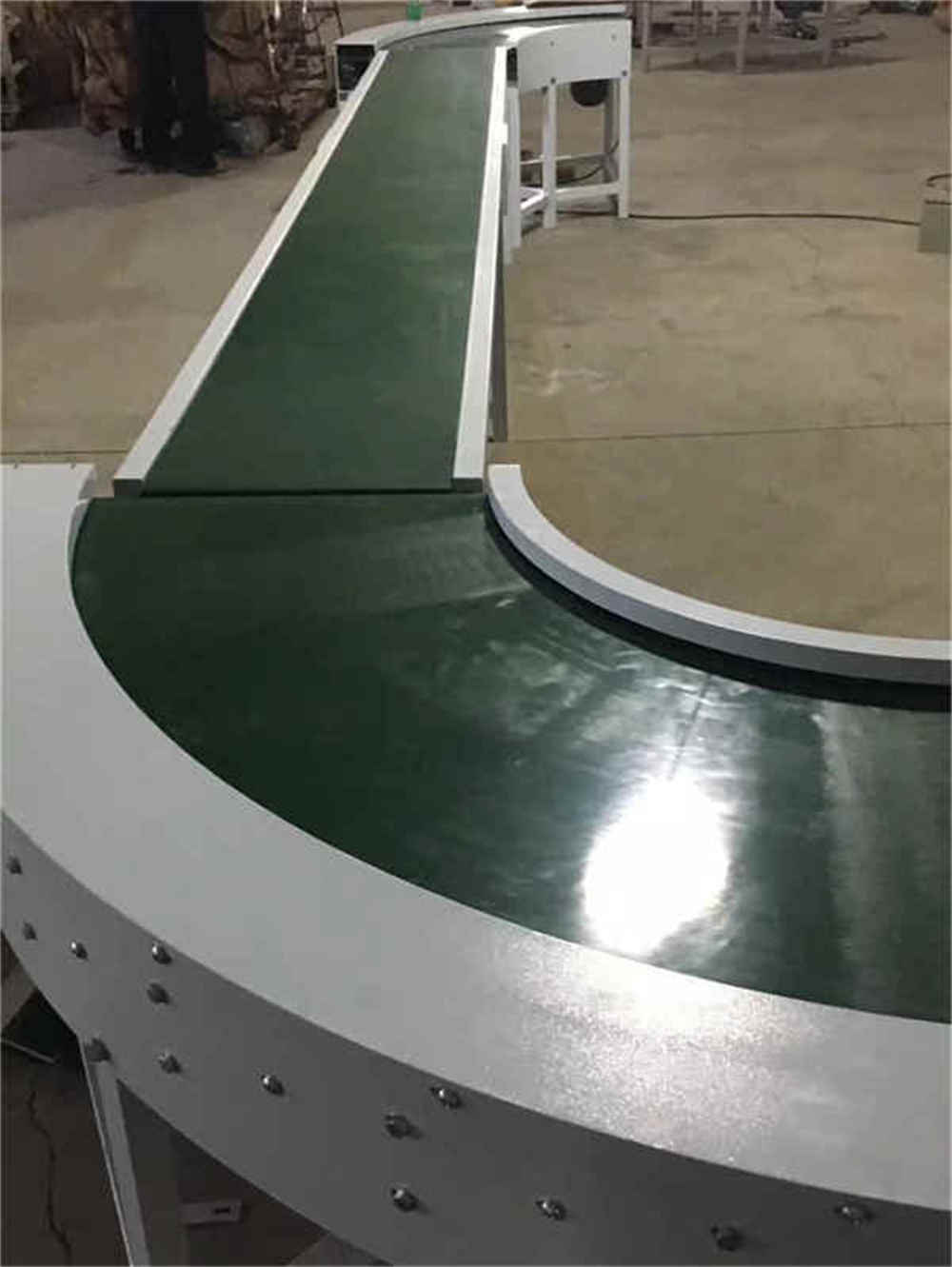

90 Degree Roller Turning Machine

90 Degree Roller Turning Machine

Technical Agreement

90 Degree Bend Conveyor

Basic requirements:

Roller Conveyor Turning Conveyor with Supporting Bandwidth of 600

Table height: 750mm; Load 50kg,

Rotary diameter: 2000mm

Appearance painting: to be determined

Motor reducer: SEW

Processing requirements of 90 Degree Roller Turning Machine:

Taper roll carbon steel galvanized, frame rectangular pipe sprayed;

Technical note of 90 Degree Roller Turning Machine:

1. SEW motor 1.1KW, 380V, 50HZ, 3P;

2. Speed: 72m/min;

3. Taper roll carbon steel galvanized, frame rectangular pipe sprayed;

4.Quantity: 4 sets.

Supply Range Of 90 Degree Roller Turning Machine

1 | 90 Drum Turning Machine | Table | 4 |

Contains the following equipment: | |||

1 | Roller | root | 56 |

2 | Inner and outer plates | set | 4 |

3 | Outrigger | branch | 12 |

4 | Pull rod | branch | 8 |

5 | Adjusting foot | individual | 16 |

6 | Chain cover | piece | 4 |

7 | Motor plate | piece | 4 |

8 | Sprocket wheel | piece | 4 |

9 | chain | piece | 56 |

10 | SEW Reduction Motor | set | 4 |

11 | parts | set | 4 |

Working Conditions

1. Work system: three-shift production, 8 hours per shift, no less than 300 working days per year, 24 hours continuous operation.

2. Power parameters: 380V AC50HZ voltage fluctuation range +-10%.

3. Operating conditions: ambient temperature 10-40 C, relative humidity 10-90%.

After-sales Technical Services

1. All machines shall be guaranteed free of charge for one year from the date of installation.

2. After-sales service line provides technical support 24 hours.

More information, please contact with me at any time!

Ady

Whatsapp:+86 15634865861

Related Products

Submitted successfully

We will contact you as soon as possible