PE Top Film Bottom Film

Usesage of PE Top Film Bottom Film :

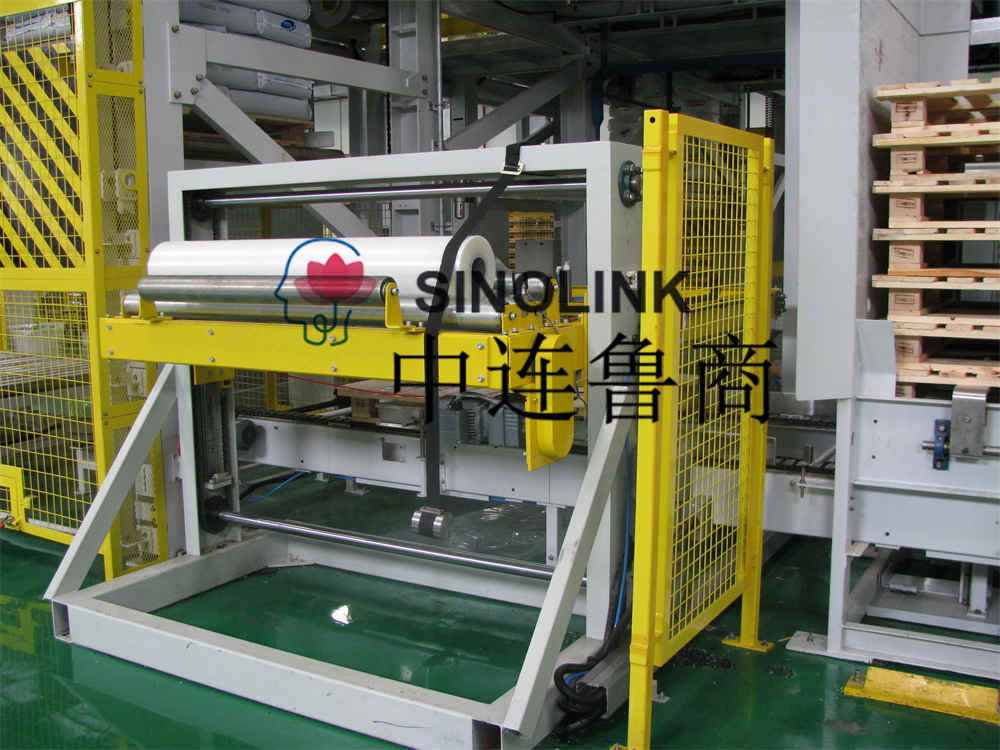

With the use of automatic topping film wrapping machine, the use of topping film machine to automatically cut the topping film, automatically cover to the top of the pallet goods, protect the goods from rain, dust, moisture, and then cooperate with the wrapping machine, wrap the topping film tightly with the wrapping film, and use the stretch film with PE topping film to play the function of dustproof, moisture-proof and anti-scattering.

PE Top Film Bottom Film Specifications:

Material, name: PE covered film

Film width: 1350mm

Thickness: 80 μm

Outer diameter: 260mm/350mm

Core inner diameter: 76.2mm

Single roll weight: 50kg/100kg (net weight)

Material of PE Top Film Bottom Film :

Polyethylene (PE) film

PE film has moisture resistance, low moisture permeability, is a blown film, thick texture, not easy to stretch and deform.

Production process:

Film blowing machine is a mechanical equipment that heats and melts plastic particles and then blows them into a film. First of all, the dry polyethylene particles are added to the hopper, and the weight of the particles themselves enters the screw from the hopper, when the pellet is in contact with the thread bevel, the rotating oblique edge produces a thrust perpendicular to the plastic with the inclined edge, and the plastic particles are pushed forward, and in the process of pushing, due to the friction between the plastic and the screw, the plastic and the barrel and the collision friction between the particles, and at the same time, it is gradually melted due to the external heating of the barrel. The molten plastic is filtered out of the die by the machine head to remove impurities, cooled and expanded by the air ring, and then pressed by the herringbone board, and the finished film is rolled into a cylinder by the traction roller.

Delivery picture of PE film and Effect picture of wrapping:

More information or requirements, please contact with me at any time.

Related Products

Submitted successfully

We will contact you as soon as possible