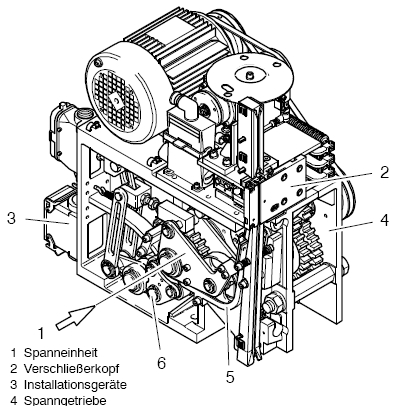

Fully Automatic Vertical Pallet Strapping Machine

Main components of vertical strapping machine

1. Basic machine frame with two columns and cross beam, vertical carriage guides and chains

2. Rack module, movable between two columns with carriage guide system

3. Carriage drive with geared brake motor

4. Strap track (chute) frame made of grooved aluminium profiles and fixed to machine frame,

spring loaded short flaps to allow strap feed at any height

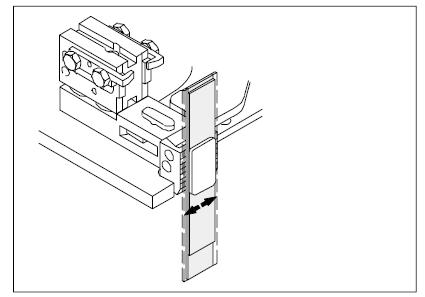

5. Lance system, to apply strap through pallet void, section height 80 mm

6. Connections to the strapping head with strap tension equalizer

7. Handling of vertical strapping machine by control panel, status of machine shown by Cyklop Touchpanel size 7“ , colour display.

Technical data of Automatic Vertical Pallet Strapping Machine

1. power supply: 3/ n, pe, (neutral wire = loading ability)

2. control voltage: 24 v dc

3. power score: max three.zero kw

4. overall weight of device: approx. 800 up to 1.000 kg

5. ambient temperature restrict: + five °c up to + 35 °c

6. peak of conveyor system: pinnacle side roller / chain of conveyor machine min. 180mm up to max. 800mm

Technical Data of Fully Automatic Vertical Pallet Strapping Machine

KA5 | ||

Strap quality and width | ||

PET | 9,0 - 18,5 mm | |

PP | / | |

Strap coil | ||

Core diameter | 406 mm | |

Outer Diameter | 600 mm | |

Width | 150 mm | |

No. of loops | 7 | |

Strap storage | 15 m | |

Strap take-off force | ca. 5 N | |

Sequence of operation:

1. The package is centralized conveyed into the strapping position.

2. A volt-free signal is given from customer’s control system to the vertical strapping machine.

3. Closing of strap track (chute) frame by moving forward lance system.

4. The rack module with the strapping head moves downwards onto the package surface. The strap is fed around the track.

5. The strapping cycle is started. The strap is pulled back, tensioned, sealed and cut off. Opening of strap track (chute) frame by moving back lance system. The rack module with strapping head moves back to the base position.

If so, transportation of package into the next strapping position and repeat strapping procedure.

After completing the programme, the machine sends a volt-free signal back to the conveyor control system to transport the load out of the machine.

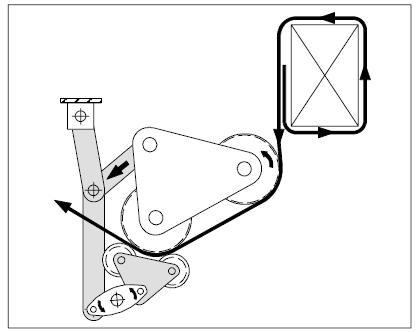

Main components of strapping head

1 Tension unit

2 Sealer cassette

3 Plugs

4 Tension gear

5 Rocking bar

6 Tension wheels

The tension unit and feed-pullback drive tighten the strap. With increasing tension the rocking bar (lever) gets lifted.

The link and pressure lever compress the tension wheels. High tension is then applied by the tension clutch only.

The strap ends are pressed and rubbed against each other until a temperature is achieved which ensures proper welding.

Control panel:

Position: Free selection within the length of 5 m cable sets

Dimensions: Height: 1.060 mm, including cabinet base 1,060

Width: 600 mm

Depth: 480 mm

Regulations: following VDE 0100/0113, EN 60204, protection class IP 54

nterfacing with Cyklop control system by volt-free signals

PLC : Siemens S7

Status of machine shown by touchpanel

General data of strapping head CFH1:

Technical data

1. Strap quality: PET

2. Strap width:12,0 mm to 19 mm

3. Strap thickness: > 0,58 mm to 1,12 mm

4. Strap feed and take-up speed: 2,9 m/sec.

5. Type of sealing: Friction weld

6. Sealing time: approx. 1,5 sec. until 2 sec. (Depending on strap and tension)

7. Tension force: 200 up to 5.500 (Sealing time Number of multistage tensioning:

8. package width: 80 mm

9. Strap centre asymmetrica 35 mm / 237 mm

10. Power supply: 3/ N, PE, (Neutral wire = loading capacity)

11. Power rating : 1,0 kW

12. Control voltage: :24 V DC

13. Weight: 79 kg

14. Painting:RAL 7035

More Information,please talk with us at any time.

Ady

WhatsApp:+86 15634865861

Related Products

Submitted successfully

We will contact you as soon as possible