Horizontal Full Automatic Strapping Machine for Pallet

Horizontal Full Automatic Strapping Machine for Pallet:

Pallet dimensions :1290 x 1290x150 mm.

Load dimensions: 1200 x 1200 mm.

Pallet height: Min.1049mm including pallet height

Pallet weigh: 1200kg/pallet

Conveyor height: 200mm. (chains conveyor)

Strapping pattern: horizonltal

Product strapped: Metal bucket

Production capacity :120Pallet/hour-2pcs stap in one pallet materials

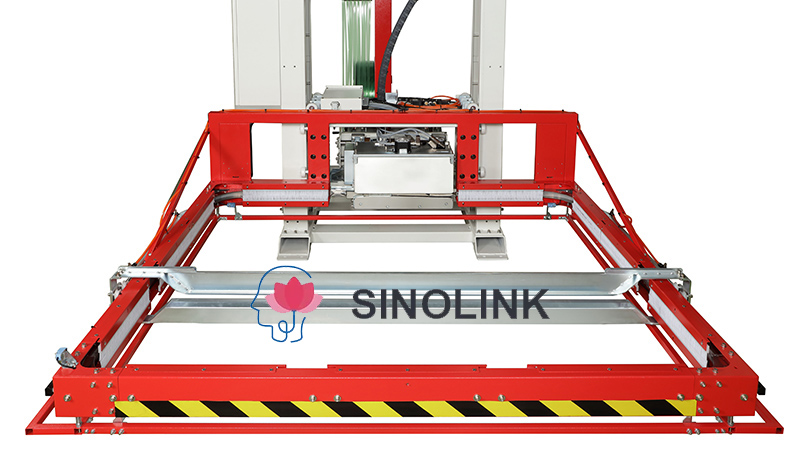

Horizontal Full Automatic Strapping Machine for Pallet is a strapping machine at one head appositively planned to a complete automation of the packaging lines. It is made with strong and heavy duty columns and has been appositively studied to allow a complete automation of packaging lines for food industries. It allows in the same time the strapping cycle.

Parameters Of Horizontal Strapping Machine heading

Strap | P.E.T. |

Useful dimensions | Width:16mm., thickness:0,6 – 0.9mm. |

Inside coil diameter | Inner core diameter 406 mm. x w160 mm. |

Functioning | Electro-mechanic pneumatic |

Strap tensioning | 50 – 3.500 N. |

Throwing speed | 2 mt./sec. adjustable by inverter |

Up/down head speed | 0.25 mt./sec. |

Cutting and welding cycle | 2.2 sec. |

Power | 400 V 3phase + N 50 Hz |

Auxiliaries | 24 V |

Installed power | 5 Kw |

Compressed air | 6 bar |

Details:

Automatic Horizontal strapping machine mod. as follows:

Hardy machine support frame

Nr.01 strapping heads with vibration welding system, particularly suitable for PET use.

Approach of the strapping head to the pallet

Strap frame driven by gear motor with rack and pinion.

Head equipped with good device design ensure four-sides PET strapping quality and strong

Automatic strapping height research device.

Adjustable dynamometrical strap tensioning device.5 to 350kg

Nr. 01 motorized reel holders to recover the exceeding strapping band and avoid surplus of material.

Nr. 01 strap guide arches in aluminium.

Possibility to use both polyester and polypropylene strap.width26mm

Powered strap dispenser for use with coils I.D. 405 mm. width 160mm complete with accumulator.

Control console with programmable logic SIEMENS S7-300 (PLC) with manual and automatic commands

By-pass

Self-checking breakdown

The machine is supplied in line with the current CE rules, following the 89/392 regulation, ex appendix 2B.

| Strapping head with vibration welding system -This head has been designed with the max simplicity to grant a very reliable functioning. -Welding made by vibration system for a constant and reliable joint efficiency -Strong and compact frame -Adjustable max tension from 50 to 3.500 Newton -Possibility to work both with PET strap. |

| Trap guide Picture is shown a strap guide for a better positioned of the strap on the product. |

| Touch screen -Control panel of the machine with PLC functions -Dedicated control panel with touch screen -Different strapping programs based on the needs of the customer -Possibility to work in manual or automatic mode -By-pass |

Detailed requirements or more information, please talk with us at any time.

Ady

WhatsApp:+86 15634865861

Related Products

Submitted successfully

We will contact you as soon as possible