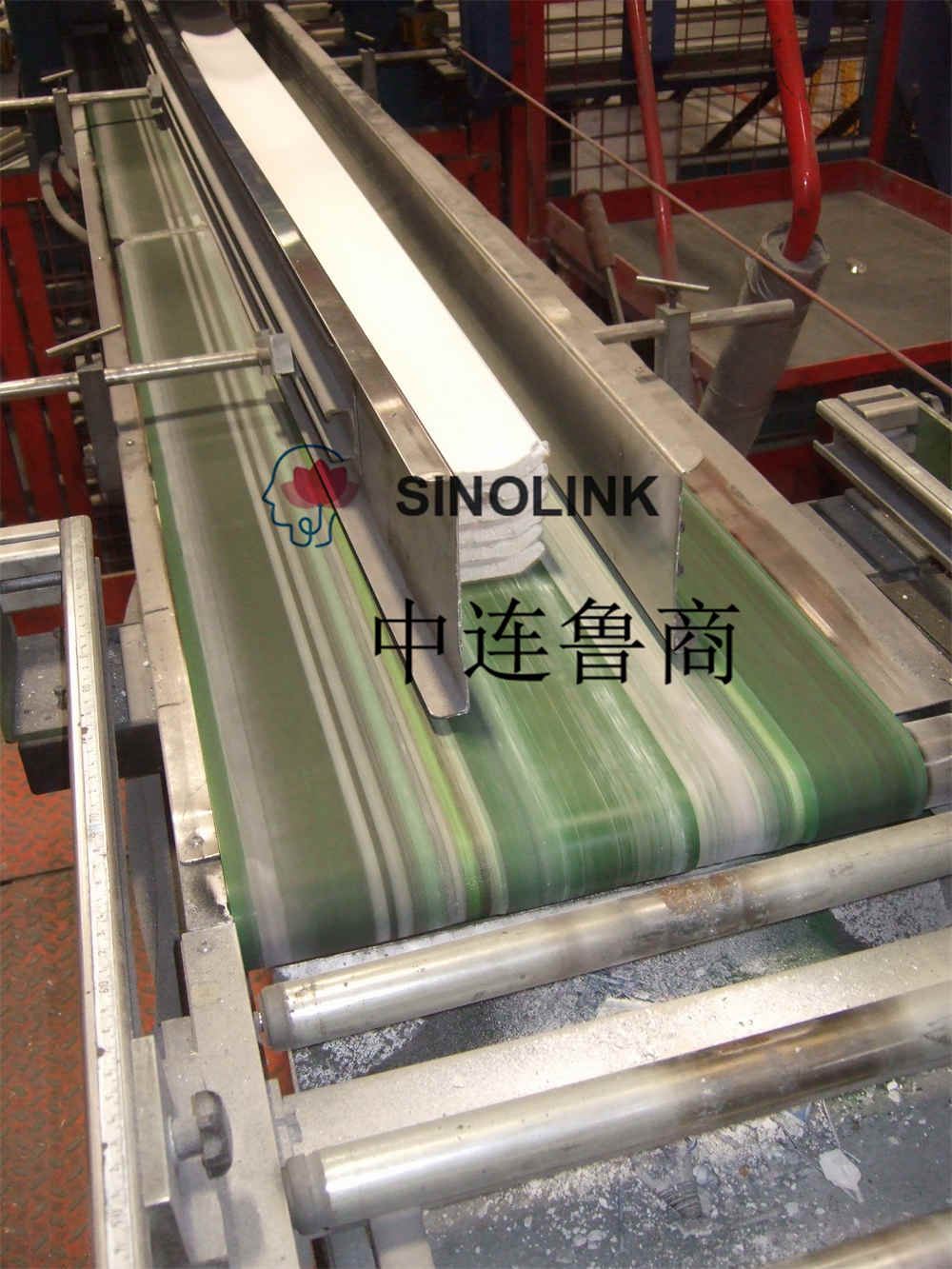

Automatic Conveying And Stacking Packaging System For Gypsum Lines Or Long Wire Sheets

Automatic Conveying And Stacking Packaging System For Gypsum Lines Or Long Wire Sheets

The automatic packaging system consists of an automated production unit composed of product conveyor, product automatic marshalling and arranging machine, product stacking mechanism, temporary storage conveyor line after stacking, cardboard temporary storage mechanism, cardboard automatic conveying mechanism, packaging preforming machine, packaging molding and output mechanism, several safety gates and fences, and control system (PLC).

Workflow Automatic Conveying And Stacking Packaging System For Gypsum Lines Or Long Wire Sheets:

The product is sent to the automatic arrangement stacking mechanism through the conveyor line, the mechanism will automatically stack the products in an orderly manner, temporarily stored on the product temporary storage line after stacking, the cardboard in the cardboard stacking storage machine will be sent to the pre-packaging host by the cardboard conveyor line, each piece of cardboard, the grabbing mechanism will grab a stack of products on the product temporary storage line into the pre-packaging machine for packaging, each completed group of preformed products will be sent to the spraying and final packaging molding host through the conveyor line to complete the final packaging molding.

Major equipment brands:

PLC : Siemens S7-300/equivalent brand:

Frequency converter: Danfoss/equivalent

Photoelectric sensor : SICK

Servo motor : Panasonic

Motor gearmotor: SEW

Servo Membrane Pack: TOYOU/SILVER

Pneumatic components : SMC

Low-voltage electrical appliance: Schneider

Touch screen : Siemens

Hot Air Adhesive System: Nordson

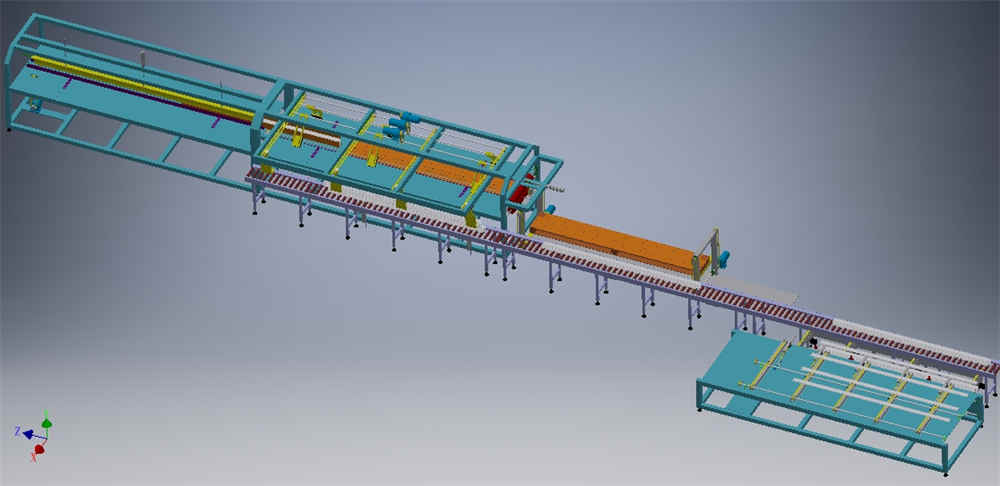

System layout diagram

Overall floor plan:

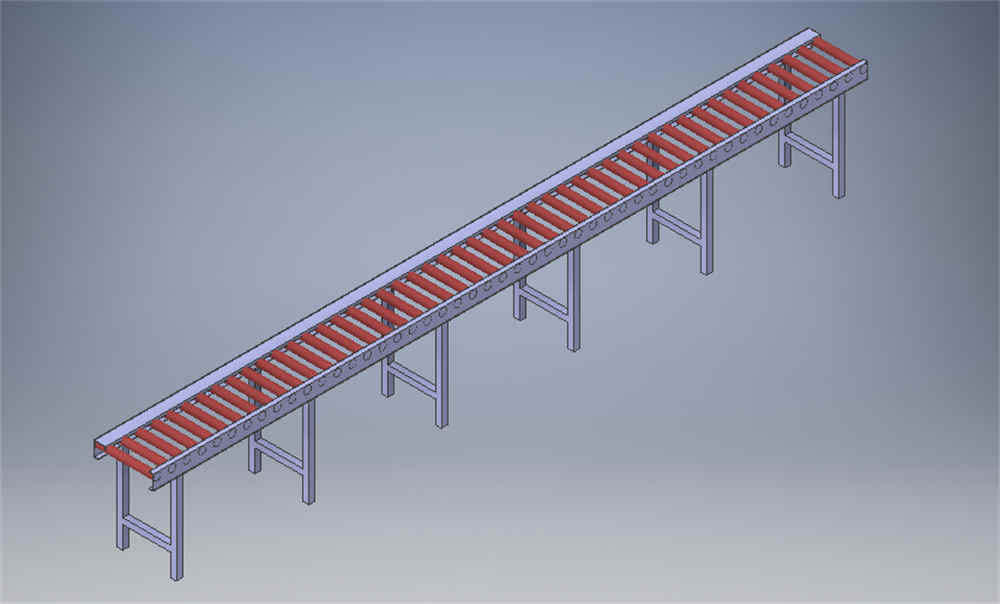

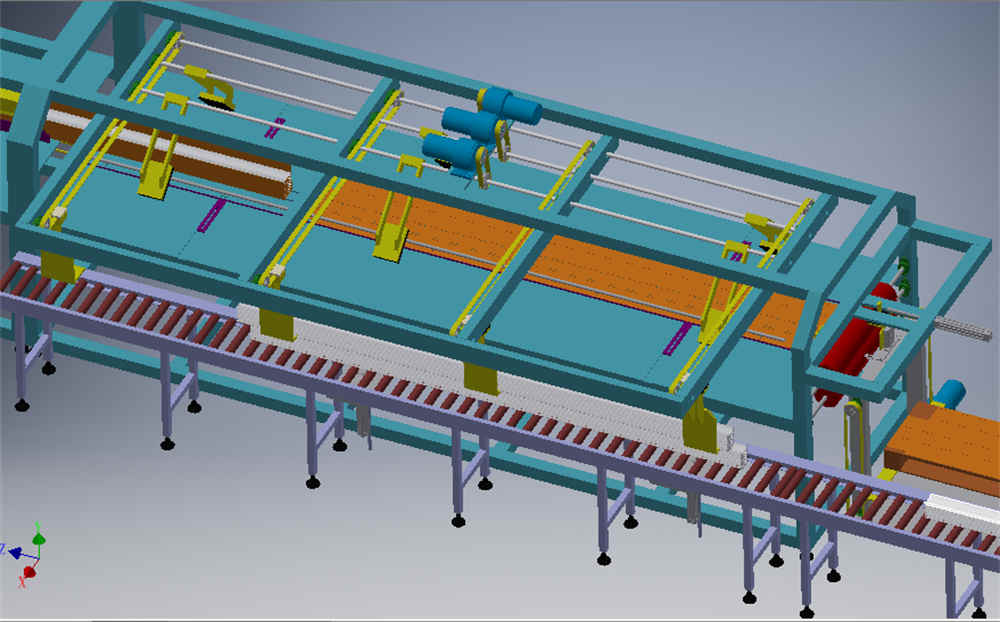

Product conveyor line and product arrangement stacking mechanism:

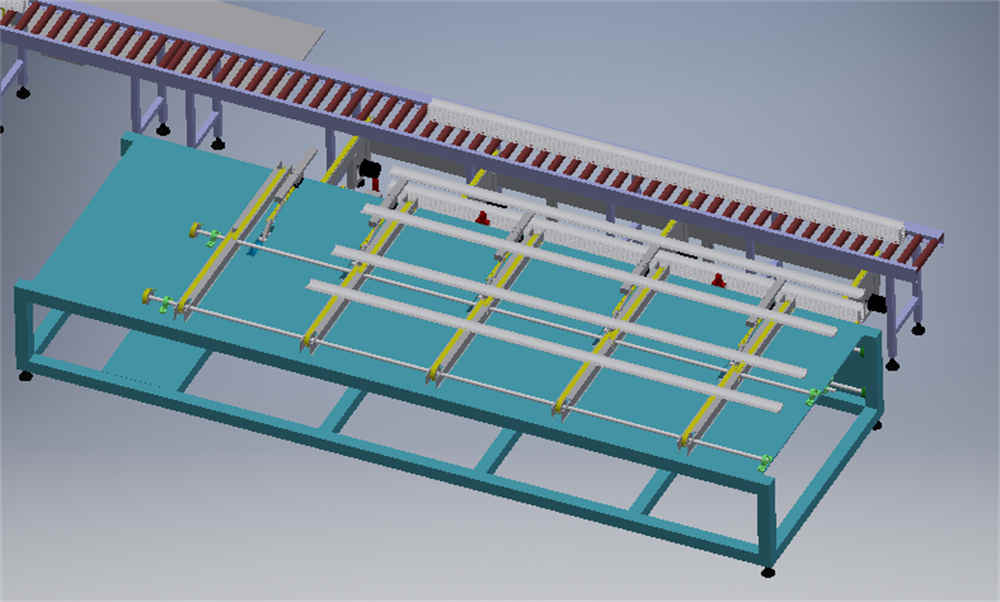

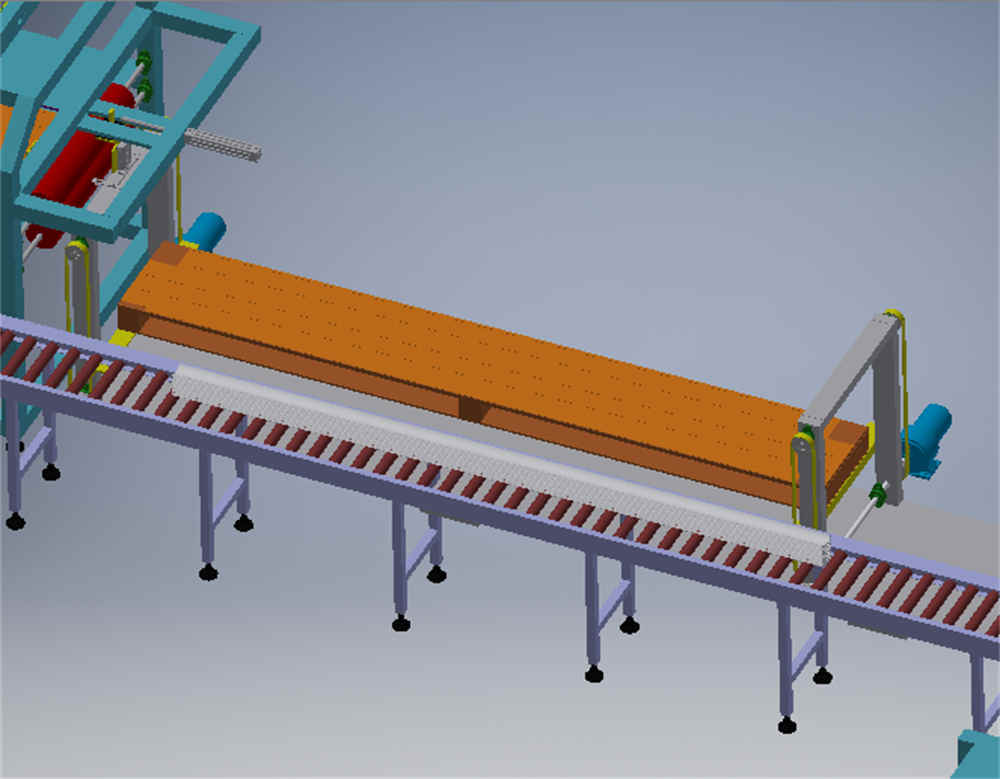

After stacking, the product is temporarily stored on the conveyor line:

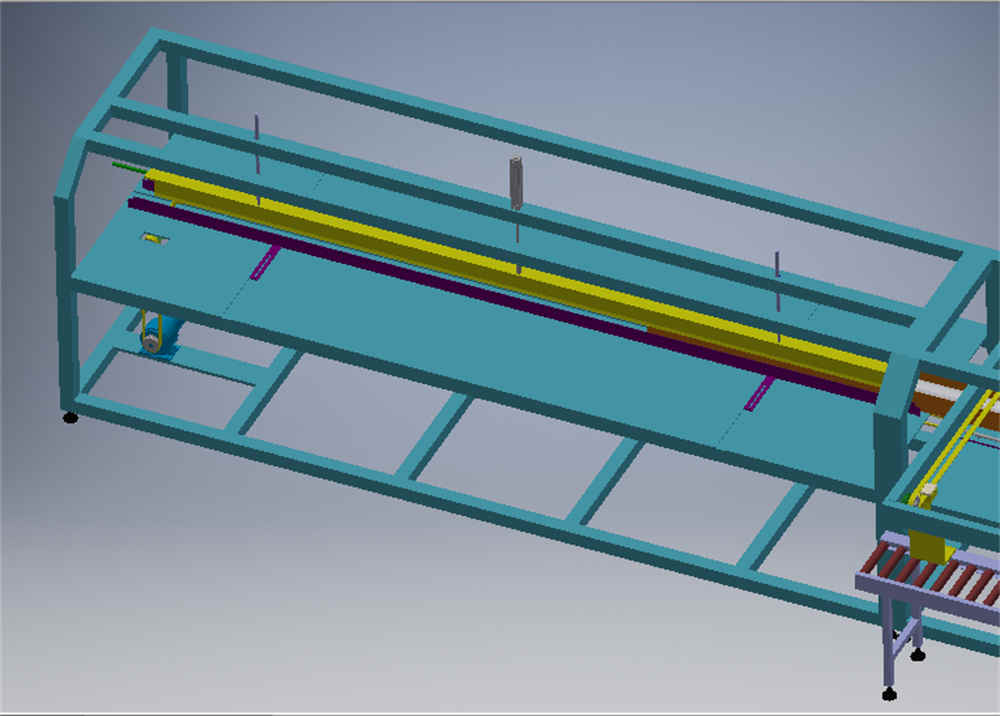

Cardboard stacking storage mechanism:

Cardboard conveying and packaging preforming host:

Packaging molding host glue spraying system and output:

More information, please contact with us at any time.

Ady

WhatsApp:+86 15634865861

Related Products

Submitted successfully

We will contact you as soon as possible