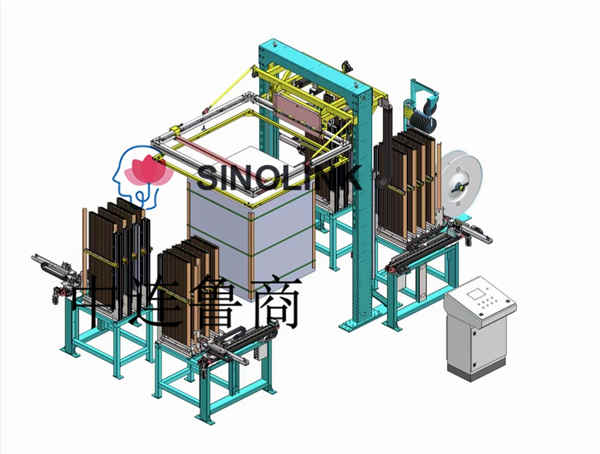

Full Automatic Extended Corner Protection Horizontal Strapping Machine

Full Automatic Extended Corner Protection Horizontal Strapping Machine

It is a fully automatic online assembly type packaging equipment, which can be connected with the front-end palletizer to form a fully automatic packaging production line. It adopts strong steel body columns, which is very suitable for automated production lines.

Features of Full Automatic Extended Corner Protection Horizontal Strapping Machine

1. Steel frame structure to ensure the stable operation of the machine

2. The machine head adopts the integrated design of automatic tightening, welding and cutting belt, which is fully suitable for packing belt

3. The machine head can be moved close to the goods and then belted, avoiding the change of pallet size and some gaps are too large

4. Automatic detection device for pallet material height. The encoder controls the precise strapping position according to different stamp heights

5. Binding force can be adjusted, maximum 200kg (according to the packing head, packing head friction welding)

6. The head moves up and down by the motor and chain

7. The design of the machine head ensures that the binding force is evenly distributed around the bale

8.1 motor power at the bottom of the packing belt roll frame, can power type retracting belt, collect excess material belt, avoid too long mopping

9. The grooves are all made of anti-rust material

10. PET strapping belt, belt width 9-16mm, thickness 0.5-0.9mm, interface width 27mm

11. PP packing belt, belt width 12mm, thickness 0.6mm, polypropylene, with 2m as the testing standard, thickness tolerance should not exceed ±0.05mm, width tolerance should not exceed ±0.5mm, deflection slope (strapping belt straight, point A to point B) can not exceed 20cm, tensile strength is not less than 100kg, curvature rate does not exceed 5%

12. Motor power packing belt reel, suitable for using the inner diameter of the belt roll 405mm, the thickness of the roll 160mm, with a lock, the replacement of the belt is convenient and fast, one or two minutes.

13. The whole electronic control system adopts editable Siemens program control, with manual and automatic modes

14. Siemens touch screen, Chinese/English operation interface

15. Side function, no belt

16. Fault alarm display detection.

Strapping Head System

1. The design of the machine head is simple and reliable, and the working performance is stable; 2. Automatic belt feeding, tape, welding and cutting tape, motor plus mechanical working mode, stable performance, the result is not only the belt's own binding force to the maximum play, but also make the welding place beautiful and flat; Powerful and compact frame; Adjustable binding force from 20 to 200kg, mechanical. |

Strapping Device:

Photos of the inside of the rails, you can see that the strapping straps can be quickly threaded and retracted around corners |

Touch Screen:

Control the operation cabinet, configure PLC line use; Touch screen man-machine operation interface; Different strapping modes can be equipped according to customer needs; Manual and automatic modes; You can choose not to tie through the belt machine mode. |

Corner protection machine descriptions:

1. Paper corner protection specifications: 50×50×5mm

2. The amount of not less than 80 corner protection sticks placed in each corner protection library

3. Machine parameters

4. Packaging efficiency: complete a package within 3 minutes (calculated according to the maximum external size, and including the time of paper corner protection)

5. Winding position conveyor line (self-provided by the demander)

6. Total power: ~4KW

7. Machine weight: 1000Kg

8. Working voltage: 380VAC/3 phase 5 wire/50Hz

9. Air consumption: 1000ml/min

10. Pneumatic working pressure: 0.5~0.7MPa

11. Conveyor line height: subject to the demand side

Automatic paper release corner protection mechanism (4 sets):

a. The mechanism can automatically detect and adjust the installation position (the center of the workpiece and the center of rotation of the winding machine basically coincide).

b. It can detect the margin of paper corner protection and can realize automatic warning, and then manually replenish the paper corner protection.

c. After the paper corner is placed, the two surfaces adjacent to the workpiece edge are aligned without gaps, and there is no skew phenomenon.

d. 4 paper corner protectors are installed and installed vertically, subject to the schematic diagram provided by the demander.

e. The whole process of placing paper corner protection realizes unmanned operation, and the equipment is in operation.

f. The demander provides the specifications of the paper corner protection for confirmation, and the bottom surface is used as the reference when placing the paper corner protection.

g. Servo motor control, more accurate

h. Since there are four heights of the palletized goods on the demand side, it is necessary for each corner protector to wear four corner protection silos, and the corner protection machine control system should have a communication function, and after the demand side issues the stacked specifications to the supplier, the corner protection machine automatically grabs the corresponding specifications of the corner protection for placement

More information, please contact with us at any time. We can design according to your requirements.

Ady

WhatsApp:+86 15634865861

Related Products

Submitted successfully

We will contact you as soon as possible