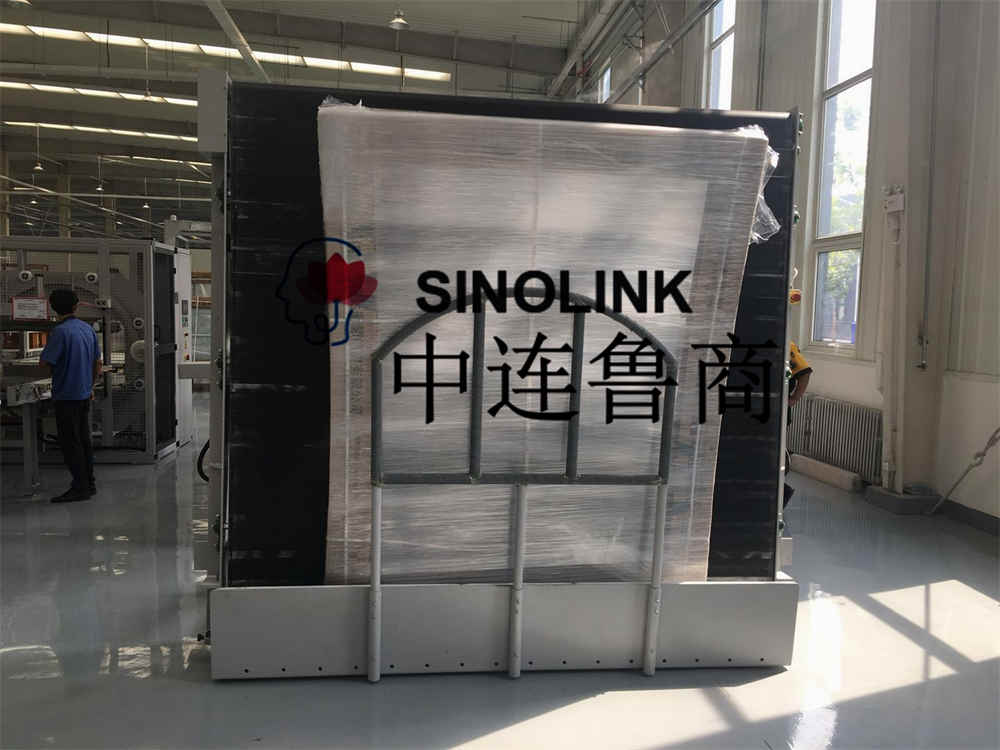

Automatic Door And Window Wide Horizontal Wrapping Winding Packaging Machine

Automatic Door And Window Wide Horizontal Wrapping Winding Packaging Machine Overview:

1. This wrapping machine is a special equipment for automatically winding stretch film onto the plate. It plays a role in preventing the packaging of bulk goods, thereby protecting products, saving packaging costs, reducing labor intensity of workers, and improving the packaging effect of special equipment.

2. Put the plate on the conveyor line, and the goods transported upstream are transported to the packaging machine station through the conveyor line, set the packaging parameters, and manually start the packaging machine to realize the continuous packaging process. Convey out of the packing station to the next section of the conveyor line. Complete the wrapping package. The next cargo circular packaging begins.

Technical parameters of Automatic Door And Window Wide Horizontal Wrapping Winding Packaging Machine

1. Product specifications and packaging requirements

Packaging: doors and windows

Width: 1000mm-2400mm

Thickness: ≤ 120mm, ≥80mm

Length: ≥1200mm, ≤2400mm

2. Packaging materials

Use a fixed size wrapping film

LLDPE stretch film

Thickness: 20-30μm

Film width: 500mm (fixed size)

Inner diameter of paper cylinder: 76.2mm

Maximum outer diameter of film roll: 240mm

Supply Scope:

1. Main unit (1 set)

Membrane frame drive trolley:

Diaphragm drive trolley specification: 2700mm

The membrane frame can be adjusted at an adjustable speed of 12m/min

Trolley speed: ≈7 laps/min

Power supply: 380V/50HZ

Membrane frame trolley drive motor: domestic well-known brand

Trolley drive motor power: 1.5kw

The floor board is made larger and thicker

Floor plate thickness: 16mm

Pneumatic topping device

Pneumatic pressure top, two sets

Downward pressure stroke: 300mm Can be controlled individually, plus button box operation

Side pressure top stroke: 300mm Can be controlled individually, plus button box operation

Ensure that the 80-120mm thick doors and windows conveyed by the upper part of the conveyor can be pressed down after pressing down

Rollers are used to secure the material and allow it to be transported smoothly

Membrane rack device

Use fixed specification 500mm winding film;

Winding film material: LLDPE, linear polyethylene

Winding film thickness: 15-25μm

Outer diameter of film roll: 240mm

Film roll core width: 520mm

The diaphragm frame tension is mechanically adjustable

The driving speed of the diaphragm frame drive trolley is adjustable in frequency conversion

It can meet the head and tail winding function

It can meet all the winding functions of goods

Membrane frame drive trolley drive mode: chain

Diaphragm frame drive trolley size: width 2700mm× height 400mm (subject to actual design size)

Automatic upper film breaking device

After winding, the specially designed membrane clamping device automatically cuts off the film and clamps the membrane head

The film is cut off with a knife

Pneumatic components are used: AirTAC

Air consumption: 1000ml

Air pressure: 0.4-0.6MPa

2. Feeding belt conveyor and discharge roller conveyor (1 set each)

Feeding belt conveyor

Split installation with host

Conveyor line speed: 2 m/min (max)

Belt width: 2500mm

Length of incoming conveyor: 2500mm

Conveyor length: 3000mm

Conveyor geared motor: domestic well-known brand

Drive motor power: 0.75KW

Height: 900mm (subject to actual design)

Belt thickness: 3mm

The conveying speed of the feeding belt conveyor is adjustable in frequency conversion;

The pneumatic centering device is automatic induction of photoelectric switch, automatic pneumatic side pressure, automatic alignment of the incoming window, and the centering stroke is 600mm;

Discharge roller conveyor

Conveyor line speed: 2 m/min (max)

Conveying effective surface width: 2500mm

Conveying length: 2500mm

Conveyor geared motor: domestic well-known brand

Drive motor power: 0.75KW

Height: 900mm (subject to actual design)

Belt thickness: 3mm

Roller diameter: 60mm

Roller spacing: 127mm

The speed of the discharge roller conveyor is adjustable for frequency conversion;

Other requirements for incoming and outgoing conveyors:

The photoelectric switch is slotted and adjustable up and down, which is convenient for the equipment to meet the window of different heights in and out

Adjustable stroke: 60mm.

3. Pneumatic flip feeding platform (1 set)

The original equipment belt flipping feeding device dynamic balance imbalance, vibration and noise is too intense, this design should optimize the original equipment, can not have too much shock and vibration.

Turning device:

Pneumatic flipping

The installation method of the flip cylinder adopts the same as the original installation method

Flip: 0-90°

The flip table foot switch flips to fix the foot

The roller at the corner of the 'L' shape at the bottom of the tilting table uses a non-powered roller, which can be connected with the non-powered roller in the window line of the demand side

For safety reasons, the outside of the non-powered roller line of the turning device is added with a circular arc-shaped round tube (the outer surface of the round tube is rubberized), the diameter of the round tube: 40mm, the wall thickness: 3mm, the highest point: 1600mm, connected on both sides of the non-powered roller of the turning table, connected by connectors, easy to disassemble and assemble

Flip table belt conveyor

Conveyor line speed: 2 m/min (max)

Roller width: 2500mm

Belt conveyor length: 2500mm

Conveyor geared motor: domestic well-known brand

Drive motor power: 0.75KW

Height: 900mm (subject to actual design)

Belt thickness: 3mm

The speed of belt conveyor is adjustable for frequency conversion;

Flip platform flipping angle: 0°-90°

Non-powered roller height from the ground: 90mm (consistent with the height of the non-powered roller in the window line of the demand side).

5. Control system and equipment performance (1 set)

OMRON PLC control;

OMRON touch screen operation, easy and clear operation;

The drive motor can be adjusted for frequency conversion;

The photoelectric switch automatically senses the position of the cargo in operation;

Mechanical pressure roller to realize side pressure forming;

Suitable for product packaging with a length greater than 1200mm.

6. Electrical control system

PLC Omron (Japan)

Frequency converter OMRON (Japan)

Touch Screen MCGS (China)

Photoelectric switch Corey (Switzerland)

Main device Schneider (France)

Low voltage electrical appliances Schneider (France)

Stroke switch Schmersel (Germany)

Proximity switch Omron (Japan)

Pneumatic components AirTAC

Main motor Domestic well-known brand

7. Other requirements

There are four improvements to the original equipment:

1. Equipment body color: RAL7012, equipment protective color: RAL7047, belt color: RAL7012 or RAL7047, not applicable to green belt.

2. The color of the control cabinet should be consistent with the color of the equipment body.

3. The balance of the flipping feeding belt should be reasonably designed, without too much shock and vibration, and the original speed remains unchanged.

4. The gas pipes and wire lines involved in the equipment should be concealed and standardized, and the industrial design aesthetics of the line gas path should be ensured through the trunking and other methods as much as possible.

More Information,please talk with us at any time.

Ady

WhatsApp:+86 15634865861

Related Products

Submitted successfully

We will contact you as soon as possible