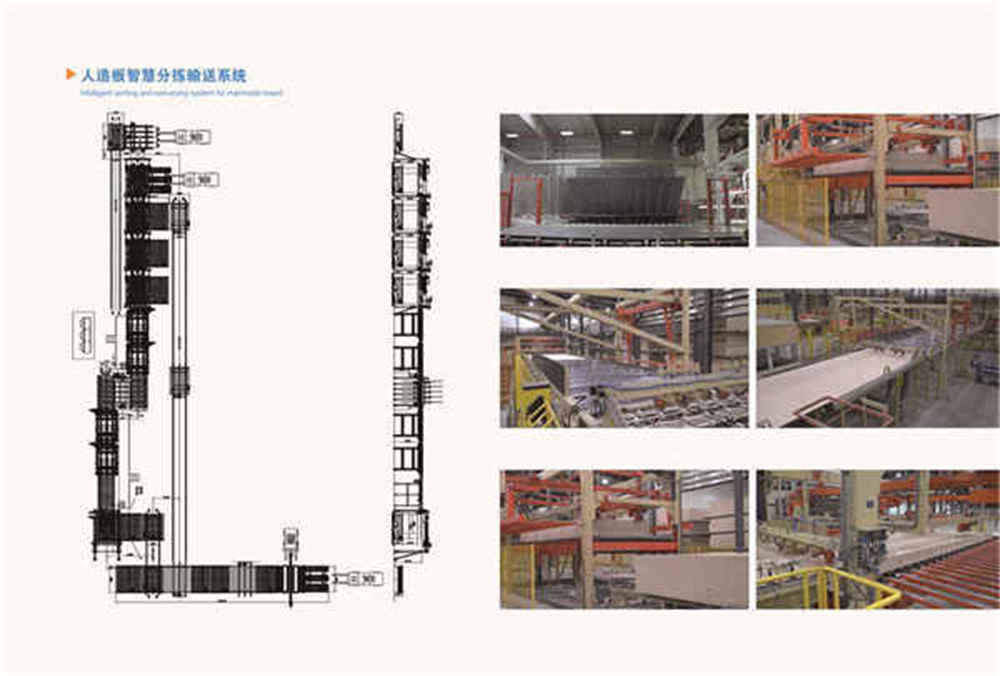

Intelligent Sorting And Conveying System For Manmade Board

Intelligent Sorting And Conveying System For Manmade Board

Product specifications and basic requirements for sorting and packing:

1. Length: 2440mm

2. Width: 1220mm

3. Height: 800 -1400mm (3m³ per plate fixed by volume)

4. Monolithic plate thickness: 8-25mm

5. Output: 1000m³/day (2 shifts/day, 8 hours/day)

6. Sorting accuracy: 99.9%

7. Sorting capacity: 19-20 sheets/min (based on 12mm thickness)

Classification requirements:

1. 98% of the plates are Class A (excellent), and three Class A (excellent) stacks are set for sorting;

2, 2% for Class B (foreign products and waste products), sorting and setting a category B (other foreign products and waste products);

Packing efficiency: 15-25 pallets/hour

Other parameters:

Sanding plate stack height 1200mm

The elevation of the whole pallet is 800mm;

Conveying speed of the whole pallet: 11m/min;

Veneer conveying speed: 120m/min (50Hz, frequency conversion)

Veneer conveying elevation: 2500mm

Stack height after plate inspection: 1200mm

The elevation of the whole stack after inspection: 800mm

The conveying speed of the whole stack after plate inspection: 11m/min

Protection plate conveying speed: 11m/min

Protection stack height: 400-500mm

Protection board veneer thickness: 12-50mm

B-class plate inspection plate after plate inspection plate stack height: 1200mm

Packing line working level: 800mm

Reducer brand: packaging equipment main motor reducer using SEW, other parts of equipment motor reducer using Boneng or equivalent quality brand, installed total power: ≈80KW

Remarks: Seller's scope of supply: complete machine supply; Buyer's scope of supply: wires and cables connected to the motor and fuselage junction box and each switch.

S.N | Name | QTY(Unit) | Description |

1 | Move the trolley longitudinally | 1 | Moving stroke: 155000mm, working length: 3100mm, working height: 800mm, roller speed: 10m/min, motor power: 2.2kw (frequency conversion speed regulation), walking speed: 20m/min, motor power: 2.2kw (frequency conversion speed regulation, braking) |

2 | Transition roller table | 7 | Working length: 2200mm, height: 800mm, roller speed: 10m/min, power: 1.1kw, frequency conversion speed regulation |

3 | Lateral movement trolley | 1 | Moving stroke: 17000mm, working length: 3100mm, working height: 800mm, roller speed: 10m/min, motor power: 2.2kw (frequency conversion speed regulation), walking speed: 20m/min, motor power: 2.2kw (frequency conversion speed regulation, braking) |

4 | Longitudinal forklift roller table | 1 | Length: 3100mm, height: 800mm, roller speed: 10m/min, power: 1.1kw, frequency conversion speed regulation |

5 | Inlet plate hydraulic lift table | 2 | Roller speed: 10m/min, motor power: 0.75kw (brake), oil pump motor power: 7.5kw, lifting stroke: 1700mm, carrying capacity: 5 tons |

6 | 2 | Working height: 2500mm, push plate thickness: 8-18mm, push plate motor power: 2.5kw (servo, brake, encoder), splint roller motor power: 2.2kw (frequency conversion speed regulation) | |

7 | Sweeping device (or brush roll) | 2 | Working height: 2500mm, working width: 1400mm, motor power: 2%x1.5kw |

8 | Belt conveyor | 5 | Working height: 2500mm, motor power: 2.2kw (frequency conversion speed regulation), working width: 1400mm, roller speed: 20-90m/min |

9 | Board inspection system | 1 | Wood-based panel inspection technology is world-leading |

10 | Flap conveyor and flap conveyor | 1 | Number of grids: 36mm, flap motor power: 2%x3kw (frequency conversion, with brake), conveyor working height: 2500mm, conveyor motor power: 2.2kw%x2 (frequency conversion speed regulation), working width: 1400mm |

11 | Inclined roller conveyor | 1 | Working height: 2500mm, motor power: 2.2kw (frequency conversion speed regulation), working width: 1400mm, roller speed: 20-90m/min |

12 | Stack conveyor (including transition roller table) (serial number 12) | 1 | Working height: 2500mm, motor power: 3kw + 0.55kw + 2.2kw (frequency conversion speed regulation), working width: 1400mm, clamping roller working speed: 20-90m/min, clamping roller motor power: 2.2kw (frequency conversion speed regulation) |

13 | 2 | Device Name: | |

14 | Stacker (1, Class A plate stacker (3 stations) 2, Class B plate stacker (1 station)) | 4 | (3) Serial number 13.1 for Class A plate stacker (3 stations) (3 Class A plate stackers) |

15 | Outlet hydraulic lift roller table | 1 | (4) Serial number 13.2 for Class B plate stacker (1 station) (1 x Class B plate stacker) |

16 | Pad (or protective plate) transporter | 1 | Working width: 1400mm, belt motor power: 2.2kw (frequency conversion speed regulation), belt working speed: 20-90m/min, clamping roller working speed: 20-90m/min, clamping roller motor power: 2.2kw (frequency conversion speed regulation), maximum stacking height: 1350mm |

17 | The pad (or protection plate) moves the roller table | 4 | Chain speed: 10m/min, motor power: 0.75kw (braking), oil pump motor power: 7.5kw, lifting stroke: 1600mm, carrying capacity: 5 tons |

31 | Pad (or protection plate) transition roller table | 1 | Working length: 3100mm, height: 800mm, chain speed: 10 m/min (frequency conversion speed regulation), motor power: 3kw, subject to the actual design |

More information, please contact with me at any time!

Ady

Whatsapp:+86 15634865861

Related Products

Submitted successfully

We will contact you as soon as possible